What Is a Pressure Reducing Station? Everything You Need to Know

June 23, 2025

What Is a Pressure Reducing Station? Everything You Need to Know

June 23, 2025What Is a Pressure Reducing Valve and How Does It Work?

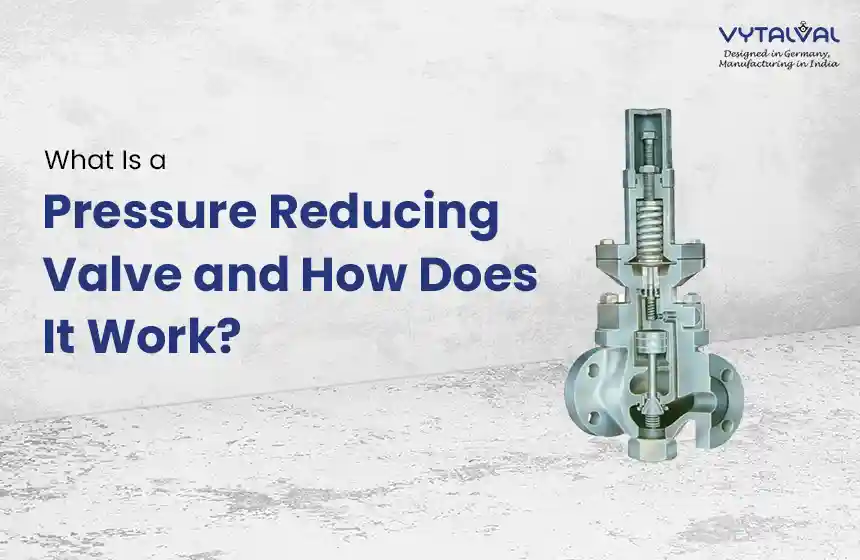

A Pressure Reducing Valve (PRV) automatically controls pressure without external power. Its main job is to reduce high pressure into a safe, lower level. These valves are commonly used in water, steam, and oil & gas industries.

In this blog, we will discuss what pressure reducing control valves are, how they work, their different operations, and why choosing the right pressure reducing valve manufacturers is important.

What is a Pressure Reducing Valve(PRV Valve)?

A Pressure Reducing Valve is a type of control valve that automatically lowers a higher inlet pressure to a lower, steady outlet pressure. Its main purpose is to protect equipment, pipelines, and processes by keeping the pressure at safe and required levels.

These valves work without the need for an external power source – they are self-operated and adjust themselves based on the flow and pressure conditions. PRVs are commonly used in water supply systems, steam networks, oil and gas industries, and many other process applications.

In a steam system, for example, a pressure reducing valve works by balancing the steam pressure against a spring mechanism. This simple but effective design is the basis for most modern PRVs.

Pressure reducing valves are generally classified into two main types, depending on how the valve opening is controlled:

1. Direct-Acting Pressure Reducing Valve

A direct-operated PRV valve is usually used in lower-capacity applications. Its design is simple as it has fewer parts. Besides, it is easy to install and cost-effective. The disadvantage of this type of PRV is that it has lower capacity and is less accurate than a pilot-operated valve.

2. Pilot-Operated Pressure Reducing Valve

A pilot-operated pressure reducing valve (PRV valve) is commonly used in industrial plants, which handles higher capacities and provides greater accuracy. The advantages of this type of PRV are that they are more accurate and have higher capacity. The disadvantages of this type of PRV valve are that they have more parts, which makes the design complicated, so they require more maintenance.

PRVs are important in a wide range of settings, from residential buildings and irrigation systems to industrial manufacturing plants and power generation stations. When left uncontrolled, the high pressure can damage equipment, reduce the lifespan of systems, and even pose safety risks.

How Does a Pressure Reducing Valve Work?

The pressure reducing valve operation is simple but effective. A PRV ensures the pressure coming into the system is not too high and keeps it at a safe and steady level. Here is how it works.

1. High Pressure Enters – Fluid or steam enters the valve at high pressure from the main supply.

2. Valve Identify Pressure – There is a spring and a flexible part like a diaphragm inside the valve. It keeps an eye on the pressure coming out.

3. Spring Adjusts the Flow – If the pressure going out is too low, the spring allows more fluid/steam to pass through. On the other hand, if it is too high, it reduces the flow.

4. Pressure Stays Balanced – The valve keeps adjusting automatically to ensure the pressure coming out stays at the level you set.

The pressure reducing valve takes high pressure in and automatically reduces it to a safer and usable level. So, you don’t need to turn a knob or switch. It works constantly in the background and keeps your pipes, machines, and systems safe from the damage caused because of too much pressure.

Where Pressure Reducing Valves Are Used

A Pressure Reducing Valve (PRV valve) is not just for water systems — it's used in many different industries to safely control pressure in liquids and gases like water, steam, and oil.

Here are a few applications of PRVs.

1. Water Systems

In residential and commercial buildings, PRVs ensure that water pressure stays within safe limits. It prevents burst pipes, leaky faucets, and water wastage.

2. Steam Systems

PRVs are also used in factories. It regulates high-pressure steam, which is used in heating, cleaning, and energy. Too much steam pressure can damage pipes, valves, and machinery.

3. Irrigation Systems

Farms and greenhouses use pressure reducing valves to distribute water evenly and prevent overwatering or damage to irrigation equipment.

4. Oil and Gas

PRVs are also useful in the oil and gas industry and manage the flow of pressurized oil or gas. They protect sensitive instruments. Also, make sure that the compressors, pipelines, and storage tanks ensure safe operation.

What are the Features of Pressure Reducing Valve?

A Pressure Reducing Valve helps lower and control high pressure in a system to a safe, steady level. It’s commonly used in pipelines for water, steam, air, and oil. Here are some simple features that make this valve important:

1. Automatic Pressure Control

PRVs automatically adjust the pressure control. They don’t require manual intervention for it. Once set, they maintain consistent output pressure, even if the inlet pressure keeps changing.

2. Compact and Durable Design

Generally, most PRVs are small and durable. They can handle tough environments such as high temperatures and corrosive fluids like oil or steam.

3. Easy Pressure Adjustment

Most PRVs comes with the external screw or knob. It allows users to set or change the outlet pressure easily without disassembling the unit.

4. Low Maintenance

Pressure reducing valves require very less maintenance and offer long service life if installed properly.

5. Safety Improvement

PRVs keep pressure levels within the safe range. So, it help prevent equipment damage, leaks, or dangerous system failures.

6. Cost and Energy Efficient

Pressure reducing valves reduce pressure so the system uses less energy and fluid. It ultimately lowers utility costs and improve overall system efficiency.

What are the Benefits of a Pressure Reducing Valve?

A pressure reducing valve offers various benefits. Therefore, it is a smart investment for any fluid, steam, or irrigation system.

- It protects equipment. High pressure can damage pipes, fixtures, or joints. A pressure reducing valve helps prevent premature damage and reduces maintenance costs.

- You can enjoy improved safety. Sometimes, too much pressure can cause system failure or accidents. PRVs are safety valves that silently keep operations secure.

- It saves energy. Lower pressure usually means reduced energy. In a water system, it avoids unnecessary flow, while in a steam system, it minimizes heat loss.

- PRVs offer consistent performance. Generally, fluctuating pressure can disrupt operations. So, PRV ensures stable performance by improving productivity and efficiency.

How to Choose the Right Pressure Reducing Valve Manufacturer?

There are so many options available, so it is challenging to select the right self acting pressure reducing Valve manufacturers in India. Here are a few key factors that you should consider while looking for the right manufacturer.

1. Quality Standard – You must look for ISO-certified manufacturers.

2. Material Selection – Select a valve which is made from a high-quality material suitable for your fluid type.

3. Customization Options – Consider a manufacturer that offers customization options. Some systems require specially designed PRVs for pressure, temperature, or fluid compatibility.

4. Customer Support – Choose the manufacturer that provides good after-sales service, as it ensures long-term satisfaction.

5. Made in India – Go for the local pressure reducing valve manufacturers in India as it can reduce costs and shipping time.

Why Choose Vytal Control for PRV Valve in India?

Vytal Control is a reliable name in the industry. Top-notch quality, innovation, service, and on-time delivery are their USPs. So, whether you’re looking for a PRV valve for your residential building, industrial steam or high-pressure oil pipeline, Vyatal Control offers high-quality solutions customized according to your needs. They have decades of experience and a strong commitment to customer satisfaction. All their products are robust, accurate, and built to last.

Their wide product range and industry-specific customization make them one of the most trusted names in the pressure reducing valve India market.

Conclusion

A pressure reducing valve might look like a small component, but it plays a crucial role. It protects systems, improves safety, saves resources, and ensures consistent performance. So, whether you want to manage water, steam, gas, or oil pressure, a PRV can be your best friend. If you’re searching for dependable pressure reducing valve manufacturers, you must trust a brand like Vytal Control—one of the trusted Control Valves Manufacturers in India that understands the complexity of modern systems. They are highly committed to excellence, which ensures you get the right value, the right performance, and the right support. So, get ready to upgrade your system’s safety and efficiency with Vytal Control’s high-quality.

FAQs

1. What is a Pressure Reducing Valve (PRV Valve)?

A Pressure Reducing Valve (PRV valve) is a device that lowers high water or steam pressure to a safe level. It keeps the pressure steady so your pipes, taps, and machines don’t get damaged.

It works automatically. If the pressure is too high, the valve closes a bit to slow it down. If the pressure is low, it opens more to let more flow through.

PRVs are used in homes, buildings, factories, and boilers. They help prevent leaks, reduce noise in pipes, and make your system last longer.

2. Why is a PRV Valve important?

A PRV valve is important because it controls high pressure and keeps it at a safe level. If pressure is too high, it can damage pipes, pumps, and other equipment, cause leaks, or even make the system unsafe.

With a PRV, you get:

- Protection for your system and equipment.

- Safe and steady pressure for smooth operation.

- Fewer repairs and lower maintenance costs.

In short, a PRV keeps your system safe, reliable, and long-lasting.

3. Where is a PRV used for?

A PRV valve is used wherever high pressure needs to be lowered to a safe and steady level. Common applications include:

-

Industrial systems – In steam, gas, and liquid lines to maintain safe, stable pressure for machines and processes.

-

Boilers and heating systems – To regulate steam or hot water pressure for safe operation.

-

Fire protection systems – To supply sprinklers and fire hoses with safe, controlled pressure.

-

Pipelines – In water, oil, or gas pipelines to reduce high supply pressure before distribution.

In short, a PRV is used anywhere pressure must be controlled to protect equipment, systems, and safety.

4. How does a PRV work?

A Pressure Reducing Valve (PRV) works by automatically controlling and lowering high incoming pressure to a safe, steady level.

Inside the PRV, there is a spring and diaphragm that work together:

-

If the pressure after the valve (outlet pressure) is too low, the spring pushes the valve open to let more flow through.

-

If the outlet pressure becomes too high, the diaphragm pushes back against the spring, causing the valve to close slightly and reduce the flow.

This automatic adjustment happens continuously, so even if the inlet pressure changes, the outlet pressure stays stable.

In simple words: A PRV acts like a pressure manager – it only allows the right amount of pressure to pass through, keeping your system safe and working properly.