What Is a Pressure Reducing Station? Everything You Need to Know

June 23, 2025

Understanding Safety Relief Valves: Functions and Importance

July 9, 2025

What Is a Pressure Reducing Station? Everything You Need to Know

June 23, 2025

Understanding Safety Relief Valves: Functions and Importance

July 9, 2025What Is a Desuperheater and How Does It Work

For almost 300 years, steam has been used to carry heat from its point of origin, such as in a boiler, to its point of use, including steam engines, turbines, or heat exchangers.

That's why steam is generated in boilers at high pressure and temperature and then expanded in equipment to get thermal or mechanical energy. In the condenser, this reduced steam is converted back into its liquid phase and transported back to the boiler.

Here is where desuperheaters are used to control superheat temperatures. It does not mean they only reduce steam temperatures but also use it to reduce the temperature of other gases by injecting suitable liquid condensate. In this blog, we will learn what a desuperheater is and how it works.

What is a Desuperheater?

A Desuperheater is a device used to lower the temperature of superheated steam, bringing it closer to the saturation level. This process makes the steam suitable and more efficient for use in various industrial applications.

There are different designs of Desuperheaters, and choosing the right one depends on the process requirements. According to control valve experts in India, certain key factors must be considered when selecting and sizing a desuperheating system.

In short:

Superheated steam - Steam that is hotter than normal boiling point.

Desuperheater - A device that removes the extra heat and makes steam safe and useful.

Desuperheaters are used in many places such as HVAC systems, power plants, food industries, and refineries to save energy and improve efficiency.

1. Direct Contact

In direct contact, the temperature reduction can be achieved by injecting water into the steam. This type of Desuperheater offers additional benefits and is highly efficient. The reason behind it is that it uses not only the temperature difference but also the steam-generating heat of the fluid.

Direct-contact type desuperheaters require minimal maintenance. They easily identify load variations, and using them, you can easily maintain the temperature close to saturation. In this type, spray water is converted into steam so ensuring the water is clean and of good quality.

2. Non Contact

In the non-contact type, temperature reduction can be achieved through a heat exchanger. They are usually inefficient because of the low heat transfer between the steam and the exchanger wall.

In this type of Desuperheater, frequent load changes are not identified quickly. These desuperheaters are used where any form of cooling water, like river water, is available.

What is the Use of a Desuperheater?

A desuperheater is used to cool down superheated steam or gases so that they can be used safely and efficiently. Without it, steam can be too hot for equipment or processes, leading to energy waste and possible damage.

Why Desuperheaters are Important:

-

Save Energy – It recovers heat that would otherwise be wasted and puts it to use.

-

Hot Water Supply – Provides hot water in homes, buildings, and industries by using waste heat.

-

Protect Equipment – Keeps turbines, boilers, and pipes from overheating, helping them last longer.

-

Better Process Control – Gives the right steam temperature for industries like food, power, paper, and chemicals.

-

Eco-Friendly – Lowers fuel use and reduces harmful emissions.

Where Desuperheaters are Used:

Desuperheaters are commonly used in industries such as:

- Power plants

-

Pulp and Paper Manufacturing

In short, the use of a desuperheater is to make energy systems more efficient, reliable, and sustainable—whether in homes, commercial buildings, or heavy industries.

Types of Desuperheaters

A Desuperheater is a device that reduces the temperature of superheated steam by injecting fine droplets of cooling water into the steam flow. This process brings the steam closer to its saturation temperature, making it safe and efficient to use in different industrial applications like power plants, refineries, and process industries.

There are several types of desuperheaters, each designed for different flow conditions and system requirements.

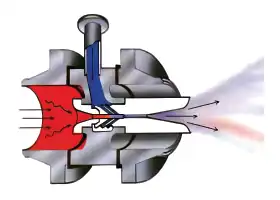

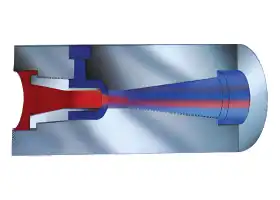

1. Venturi and Double Venturi Desuperheaters

This type uses a De Laval nozzle to create a low-pressure zone where spray water is drawn in and mixed with steam. The steam then exits through an expanding throat, which helps recover pressure.

- Works well across a wide load range (from full load to very low load).

- Spray water can be supplied at the same pressure as steam.

- Reliable performance and high turndown ratio.

Power plants, refineries, and chemical plants that need accurate steam temperature control.

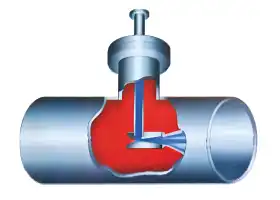

2. Attemperator

An Attemperator is a simple design that does not use a venturi section. It can be quickly installed in existing pipelines, making it a good choice for retrofitting. It is best when low pressure drops are needed.

- Sizes: 1½” to 30”

- Rangeability: 8:1 (single venturi), 12:1 (double venturi)

- Pressure Rating: Up to ANSI 2500#

- Spray Water: Can be injected at steam operating pressure

- Where it’s used: Boiler systems and heat recovery systems where installation space is limited.

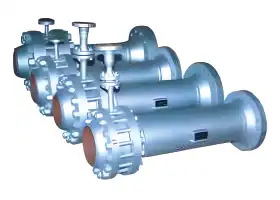

3. In-Line Venturi Desuperheater

This is a large-size version of the venturi type. It is installed directly into the steam pipeline and is specially designed for high flow applications.

- Sizes: 10” to 40”

- Why use it? Ideal for handling very large steam flows.

- Where it’s used: Large boilers, power stations, and petrochemical plants.

4. Mini Venturi Desuperheater

The Mini Venturi is a small-size desuperheater made for low flow applications. It is compact and available in sizes from ½” to 1½”. Connections can be screwed or socket welded.

- Why use it?

- Perfect for low-capacity systems.

- Cost-effective and easy to install.

- Where it’s used: Pilot plants, laboratories, and small process uni

5. Multi Nozzle (Orifice) Lancer Desuperheater

This type uses multiple nozzles to control the amount of cooling water injected. The nozzles are opened or closed by a piston actuator, which ensures accurate water injection and very fine spray distribution.

- Key Features:

- Standard turndown ratio: 50:1 (higher possible on request).

- Excellent spray quality over the full operating range.

- No need for a separate spray water control valve.

- Sizes: For steam pipes of 6” and above

- Rangeability: Up to 360:1

- Pressure Rating: Up to ANSI 2500#

- Spray Water Pressure: 5 bar above steam pressure or high-pressure boiler feedwater

- Actuator: Piston cylinder or spring & diaphragm type

- Flow Characteristics: Modified, Equal %, Linear

What Factors Can Improve Steam Desuperheating Performance?

- The desuperheating system is made of various components, not only the Desuperheater. So, to obtain the best results in terms of efficiency and costs, avoid oversizing. If the Desuperheater is oversized, it will be bound to fail because it will operate at low rates.

- Ensure the spray water is clean to avoid any deposits in the desuperheating nozzle.

- Avoid desuperheaters operating close to the saturation temperatures.

- Ensure that sufficient trapping of the downstream piping of the desuperheating system is available.

- If the temperature difference between steam and water is more, or if the pipe wall is more than ½ inch thick, include thermal sleeves or liners. It helps hot steam to flow past the liner and keep it at operating temperature.

Conclusion

A Desuperheater plays an important role in many industrial systems. It lowers the steam temperature to a usable level to improve efficiency, ensure safety, and protect valuable equipment.

In short, it is not a superhero gadget, but it still does something powerful. There are various designs of desuperheaters available in the market. However, while choosing the best fit, you need to check the operating conditions and the downstream piping system. If you're looking for the best Desuperheater valve manufacturers in India, contact Vytal Controls today!

We're the most reputable Indian brand. So, talk to our experts and get expert guidance and customized valve solutions for your needs.

Do you have any questions about Desuperheaters? Please write to us in the comments section below.

FAQ's

1. What is a desuperheater?

A desuperheater is a device used to cool superheated steam by bringing its temperature closer to the saturation level. This makes the steam safer and more suitable for use in various industrial processes.

2. What are the main types of desuperheaters?

Desuperheaters are devices that cool down superheated steam by adding water. There are a few main types, each used for different needs:

-

Spray Type – The simplest and most common. It sprays water directly into the steam line to reduce the temperature.

-

Venturi Type – Has a special shape (venturi) that mixes steam and water better, giving more efficient cooling.

-

Atomizing Steam Type – Uses extra steam along with water to break water into very fine droplets, giving precise and quick cooling.

-

Surface Type – Works like a heat exchanger. Steam and water don’t mix; instead, heat transfers through metal surfaces. Useful where water should not enter the steam.

-

Orifice / Mechanical Type – Uses fixed holes or mechanical parts to spread water evenly into the steam. Good for steady operating conditions.

In short:

-

General use → Spray type

-

Better efficiency → Venturi type

-

Precise control → Atomizing steam type

-

No mixing of steam & water → Surface type

3. Where are desuperheaters used?

Desuperheaters are used in industries where high-temperature steam needs to be cooled for safe use. They are commonly found in power plants, refineries, paper mills, food processing, textiles, and heating systems to provide steam at the right temperature for different processes.

4. What is the difference between a Desuperheater and an Attemperator?

A Desuperheater reduces the temperature of superheated steam by spraying water, bringing it closer to saturation for safe use in processes.

An Attemperator, on the other hand, is mainly used in boilers and steam lines to control and maintain steam temperature within safe operating limits.

In short:

- Desuperheater - Cools superheated steam

- Attemperator - Controls and stabilizes steam temperature