Efficient Steam Management With Steam Conditioning Valves

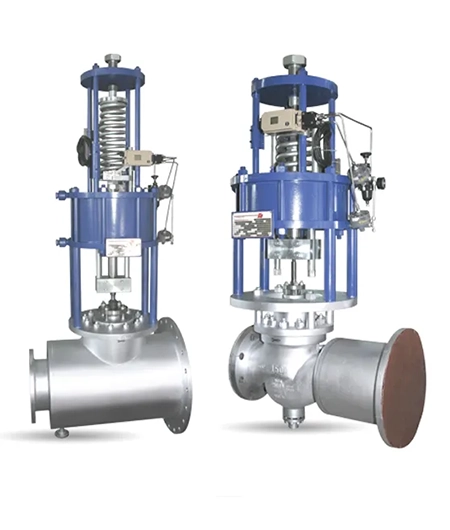

Vytal Controls Pvt Ltd steam conditioning valve with revolutionary multi-nozzle atomizer and feed-forward design adds to our latest generation of quality valves. The equipment is utilised for simultaneous pressure and temperature reduction of steam. The cooling water is introduced in the highest turbulent zone of the steam. High steam velocity at this point, results in the highest coefficient of heat transfer between the steam and water. The feed-forward design assures soft misty spray and instantaneous temperature control over the full range of steam flow.

Technical Specification

Technical Specification for Steam Conditioning Valves.

Type

Pilot & Piston Operated

Size

0.5 Inch to 16 Inch

Type of End Connection

S.W. / B.W. / F.L.

Rating

CL 150 to CL 600

Body MOC

Carbon Steel / Stainless Steel

Flow Characteristics

Linear, Equal Percentage

Benefits of Steam Control Valves

Steam pressure reducing valves offer various benefits. Here are a few key advantages.

- For high-pressure let-downs, the pressure drop is taken across concentric flow cages rather than across the seating surface, resulting in minimal seat wear.

- Pilot-operated cage design to achieve extremely tight shut-off (leakage classification ANSI # V)

- Balanced design with heavy-duty pilot spring greatly improves throttling stability at high Δ P.

- Larger outlet and outlet diffuser options give noise attenuation at optimum design conditions guaranteeing an outlet sound pressure level to 85 dBA.

- Stellied trim increases its resistance to corrosion, erosion by abrasion, galling and sticking.

- quick and economic start-up, including cold start, warm start and hot start in a lifesaving manner for critical heavy components in the boiler and turbine.

- To operate with the boiler shutdown.

- To perform warm and hot startup in a short time after a trip i.e. bring the unit back to load

- To run the unit down to house load.

- To perform a real “two-shift operation”.

- To avoid condensate losses to the atmosphere and reduce the start-up noise to the ambient outside the plant.

Talk to Our Experts!