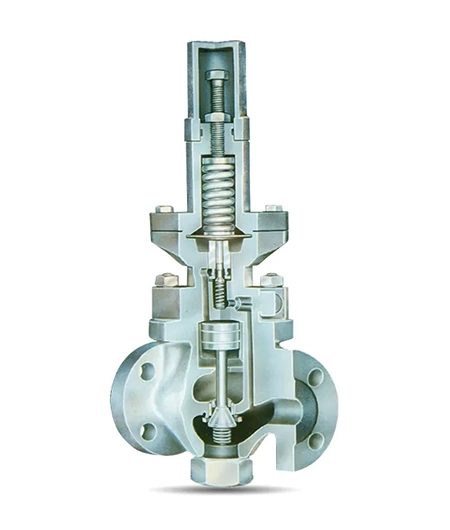

Pilot and Piston operated self actuating ‘PRV’ controls the downstream pressure with an accuracy of ± 1%, regardless of fluctuations in upstream pressure or flow rate. It can be used for steam, air, gases or liquids. Constant downstream is maintained from full flow to 10% of flow (Rangeability 10 : 1).

In the Mark I design, main valve is single seated and normally closed. Initial pressure exerted on the main valve assisted by a main spring force ensures tight shut-off. Irrespective of the valve size pilot assembly remains the same. At the same time, the main valve can be converted from a reducing valve to a Back Pressure Regulator or a Different pressure Regulator.

– Balance design unaffected by variations in inlet pressure. – Instantaneous response to changes in demand. – Full lift design achieves high flow rates. – Effective “Low Flow “ control due to single seat design. – Increased seat/chest ratio for lower velocities and quiet operation. – Stellited trim ensures tight shut-off even after prolonged use. Sizes : 1/2” to 6” Cv : 0.05 to 105 End connections : Screwed or flanged upto 600 # rating Temperature Limit : Upto 270 °C with stainless steel spring and 410°C with Inconel spring. Pressure Limit : 46 bar- To operate with the boiler shutdown.

- To perform warm and hot startup in a short time after a trip i.e. brings the unit back to load

- To run the unit down to house load.

- To perform real “two-shift’ operation”.

- To avoid condensate losses to the atmosphere and reduce the start up noise to the ambient outside the plant.

In order to avoid seat leakage on light gas services, the main valve/seat and pilot valve/seat are provided with elastomer seat seal. The elastomer material is selected to suit the duty conditions. Another important application for this type of valve, is an explosive nature of gases e.g. Hydrogen. When the gas passes through the valve at high velocity, static charges are created leading to the possibility of spark, this can be disastrous in explosive gas atmosphere. Under these circumstances, the soft seated valve is always recommended.

In order to obtain high pressure drop, normally two or more valves are installed, which is expensive and often disappointing, when the leakage of the upstream valve throws all of the Δ P on the downstream valve. In such cases, a PRV with multijet caging is recommended. The three stage pressure reduction (number of stages are decided based on critical Δ P ratio) is achieved with the help of multistage perforated cage. The design offers the following advantages: • Flow distribution leads to the noise attenuation. • Pressure drop is distributed across different stages and not at the throttling point between main valve and seat, thus reducing the trim wear. • Low cost installation and maintenance of only one valve. • Increased overall system performance.

• In cases where it is more convenient, on account of the pipe connection, to have a valve larger than is necessary to deal with the quantity of steam, we can fit smaller seats so that regulation will be satisfactory. • To avoid replacing the valve body with another of a different size when a future increase in the flow is expected in relation to that at the start of operation. • When the pressure drop across the valve is considerable, it is better to use a larger body for the advantage of rigidity.

When set pressure are in the range of 50mm WC to 2000mm WC, the regular pilot assembly cannot provide enough of controlling thrust. In order to achieve this, Vytal Controls Pvt Ltd offers Pressure Reducing Valve with a special low pressure top assembly. The assembly is supplied as a complete conversion unit for fitting to the regular pilot assembly. It incorporates a larger diaphragm, thus providing a greater effective area and improved sensitivity to very low outlet pressure conditions.

The limitation on regulator sizing is rangeability (10 : 1 in conventional valves). Very low range ability is observed in case of the steam regulator, because of its limitation to operate the main valve close to its seat (because of wire drawing). There are several ways of increasing rangeability,mainly by design/selection of proper trim characteristics.

The best way to control the Cv minimum is to provide the auxiliary plug. It regulates in the range of minimum flow rate to the minimum controllable flow rate. Once the minimum flow is achieved, the main valve takes over and operates till the maximum flow is obtained. Thus the twin plug arrangement offers multiple rangeability from 20 : 1 to several hundred.