What Is an Automatic Recirculation Valve?

An Automatic Recirculation Valve (ARC valve) is a valve that protects pumps from getting damaged when the flow of liquid is too low.

Pumps need a minimum amount of liquid to keep running safely. If the flow becomes too low, the pump can overheat or break. The ARC valve solves this by automatically sending some liquid back to the pump through a bypass line when the main flow is low.

It works on its own — no need for extra control systems — and helps the pump run smoothly and safely at all times.

Simple Benefits:

- Protects the pump when flow is low

- Automatically sends extra liquid back to the pump

- No need for separate valves or controls

- Saves space and reduces maintenance

Ensure the Optimal Fluid Flow

Vytal Controls Pvt Ltd valves are built strictly as per the German Design and installed for Boiler feed Pump protection. Also termed as Minimum Flow valves, are deployed to cater to the most demanding conditions and are one of the most critical valves installed in a power plant.

Available in globe and angle form as per the plant layout requirements. The material of construction is normally carbon steel with 17% Cr plasma nitrided trim ensuring smooth, trouble-free and everlasting performance.

A typical application would be to reduce water pressure from 120 Bar down to 1 Bar.

Technical Specification For ARC Valve

Technical Specification for Automatic Recirculation Valves.

Benefits of Automatic Recirculation Valve

ARC valve offers various advantages. Let’s check out a few of them here.

ARC valves are for ON/OFF as well as regulating service. The sizes range from 150 mm to 150mm and the ratings are up to 2500#.

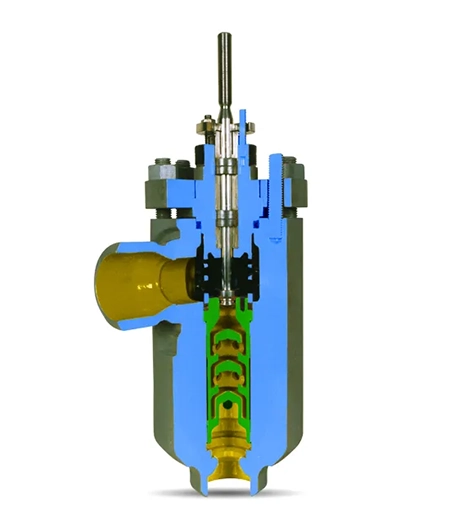

Cut section view

- Sizes : 1/2” to 6”

- Rangeability : 50 : 1

- Rating : Upto ANSI 2500#

- Characteristics : ON/OFF, Equal %, Linear, Modified

Get Expert Guidance and Tailor-Made Valve Solutions for Your Needs

FAQ

1. What is an Automatic Recirculation Valve?

An Automatic Recirculation Valve (ARC valve) is a smart device designed to protect pumps, especially centrifugal pumps, from damage when liquid flow drops below the required level. These valves ensure the pump doesn't run dry or overheat.

When the main flow is reduced or stopped, the valve automatically opens a bypass line to send liquid back to the source or tank. This keeps the pump running safely and prevents issues like cavitation, overheating, or mechanical failure.

ARC valve are widely used in industries such as power generation, chemical processing, and oil & gas, where consistent pump performance is critical.

2. Why are Automatic Recirculation Valves important for pump protection?

These valves play a key role in pump safety. They make sure that even if the main pipeline is closed or partially blocked, a minimum flow of liquid is always maintained through the pump. This prevents the pump from operating dry or overheating, which can lead to wear and costly repairs. With proper flow management, the pump runs more reliably and lasts longer.

3. How does an Automatic Recirculation Valve work?

An ARV operates automatically without the need for external controls. When the flow to the main process line drops, the valve detects this change and redirects the liquid through a built-in bypass. This keeps the pump supplied with fluid and avoids damage. Its automatic function makes it a simple and reliable solution for ensuring continuous pump operation.

4. Can these valves be customized for specific applications?

Yes, they can be tailored to fit different systems and conditions. Depending on the application, the valve can be built in various sizes and materials, and designed to handle different pressures, temperatures, and flow rates. Whether you're dealing with high-pressure systems or challenging industrial environments, the valve can be adapted to suit your requirements.