What Is a Turbine Bypass Valve System? Working, Types, and Applications Explained

September 8, 2025

Why Every Thermal Power Plant Needs a Desuperheater

October 6, 2025

What Is a Turbine Bypass Valve System? Working, Types, and Applications Explained

September 8, 2025

Why Every Thermal Power Plant Needs a Desuperheater

October 6, 2025What Is an Automatic Recirculation Valve? Function, Benefits & Uses

CIn industrial systems, efficiency and safety are paramount. One small problem or technical glitch can cause major issues like damage to the equipment, safety hazards, and unexpected shutdowns. Here is where an automatic recirculation valve can be helpful. These valves are not widely known, but they play a powerful role in protecting important machinery such as industrial pumps.

In this blog, we will discuss what the ARC valve is, how it works, its benefits, applications, and more. Let’s get started.

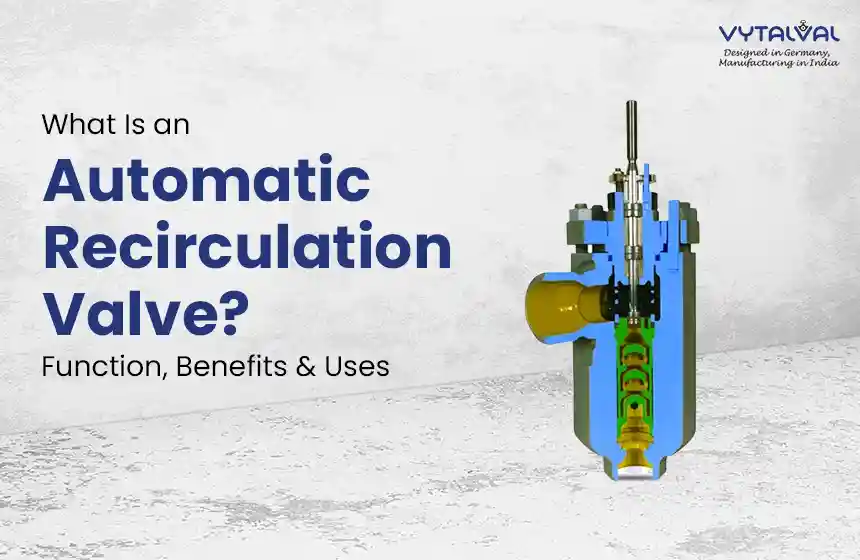

What is an Automatic Recirculation Valve?

It is a special type of control valve that protects centrifugal pump from getting damaged when the fluid flow is too low or drops below a certain level.

Simply put, it ensures that the minimum amount of liquid flow keeps flowing from the pump even when the main outlet is shut or partially closed. If the flow completely stops or becomes too low, it can overheat and damage the pump. Therefore, the ARV valve can keep things moving to prevent that from happening.

If the main route is blocked, the ARV valve automatically sends the liquid through a recirculation line and keeps the pump safe.

Why are ARV Valves Important?

The centrifugal pumps require a constant liquid flow. If the flow becomes too low or stops, it can overheat the pump, the pump can experience vibration, get permanently damaged, or suffer from cavitation.

However, the ARV valve ensures this does not happen by automatically recirculating the liquid whenever required. They act as the built-in bodyguard for your pump.

How Does ARV Valve Work?

Let’s understand how the Automatic Recirculation Valve works through the simple step-by-step process.

- Whenever the flow condition is normal, the system is working normally, and the pump is sending liquid wherever it is required, the ARV valve allows flow through the main line. In this case, the ARV valve keeps the recirculation line closed.

- In reduced flow conditions, the ARV valve senses the low flow and slowly opens the recirculation line. So, the controlled amount of flow returns to the source.

- When the no-flow condition arises, the ARV valve automatically closes the main line and opens the recirculation line fully. The ARV valve ensures that the pump is still running with the required minimum flow.

All these occur without any external power or control system because the ARV valve is fully automatic.

What are the Key Components of an Automatic Recirculation Valve?

The main components of the ARV valve are:

- Main flow line - It directs flow to the process line.

- Bypass line - It sends flow back to the pump or tank.

- Check valve - This prevents backflow.

- Spring mechanism - It controls the opening and closing of the bypass.

- Internal sensing mechanism - It detects flow rates and adjusts automatically.

What are the Advantages of an Automatic Recirculation Valve?

Automatic valve offers the following benefits.

- It protects the pump by ensuring a minimum flow at all times.

- When you have an ARV valve, you don’t need external controls because this valve works automatically without needing any sensors, power supplies, or computers.

- ARV valves reduce downtime by protecting the pump. So, systems will experience fewer shutdowns and lower maintenance costs.

- The automatic recirculation valve combines various functions into one body, so it saves space as you don’t need different valves for different functions.

- It prevents pump damage by optimizing flow, so your system will use energy more efficiently.

- When you have an ARV valve placed in your system, you will experience fewer repairs, parts, and maintenance.

Where are ARV Valves Used?

Automatic recirculation valves are used in many industries where pump handles liquid under high pressure or temperature. Here are a few:

- Oil and gas

- Power plants

- Chemical industry

- Pharmaceuticals

- Pulp and paper

- Food processing, etc.

Key Difference Between ARV Valve and Normal Check Valve

Here is how the Automatic Recirculation Valve differs from the Normal Check Valve.

| Feature | ARV Valve | Normal Check Valve |

|---|---|---|

| Function | It maintains a minimum flow and recirculates liquid. | It prevents backflow. |

| Automation | This valve is fully automatic with multiple functions | A Normal Check Valve is a simple one-way valve. |

| Pump Protection | Yes, it protects the pump. | No, it does not protect the pump. |

| Internal Mechanism | It contains complex spring and flow sensing | It includes a simple flap or disc. |

| Use Case | They are widely used in industrial pump systems. | They are used in general liquid systems. |

In simple terms, a normal check valve is basic and useful for preventing backflow, whereas an ARV valve offers full protection.

How to Choose the Right ARV Valve?

Choosing the right Automatic Recirculation Valve depends on the following factors.

- Pump size

- Flow rate

- Fluid Type

- System pressure and temperature

- Industry requirements

You must consult the expert to choose the right ARV valve for your pump system. A poorly selected valve can do more harm than good.

What are the Maintenance Tips for ARV Valves?

An automatic recirculation valve is designed to be low-maintenance, but its regular check ensures long life.

- You must inspect the valve regularly for leakage and corrosion.

- Clean the bypass line regularly to prevent clogging.

- Replace the worn-out seals or springs.

- You must use the original spare parts for the best performance.

- Test the valve movement to ensure smooth opening and closing.

Final Thoughts

An automatic recirculation valve may look small device, but it plays a major role in industrial systems. It quietly protects pumps, saves money, reduces downtime, and ensures smooth operations.

Industries that deal with high-pressure, high-performance, or sensitive fluids must consider installing an ARV valve to protect their pumps. These valves help businesses avoid costly mistakes. From oil refineries to power plants and chemical factories, these smart valves save hard-earned money for businesses.

If you’re looking for reliable solutions, always choose quality products from the trusted control valve manufacturers in India, like Vytal Control. The right ARV valve not only protects the pump but also your business.