A Complete Guide to Pressure Reducing Valves for Oil and Gas Applications

September 4, 2025

What Is an Automatic Recirculation Valve? Function, Benefits & Uses

September 10, 2025

A Complete Guide to Pressure Reducing Valves for Oil and Gas Applications

September 4, 2025

What Is an Automatic Recirculation Valve? Function, Benefits & Uses

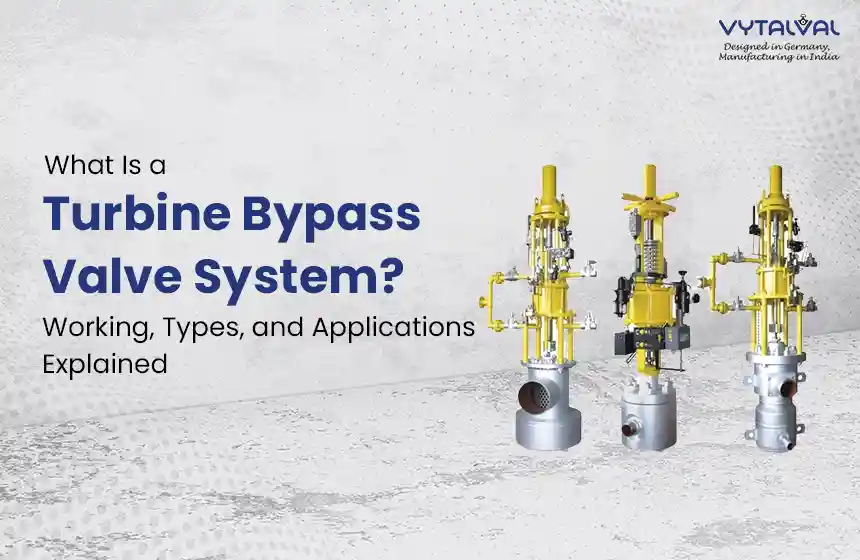

September 10, 2025What Is a Turbine Bypass Valve System? Working, Types, and Applications Explained

In the power generation industry, safety and efficiency are top-most priorities and one component that helps achieve this is the Turbine Bypass Valve. A bypass valve offers an alternative steam path whenever the steam turbine cannot accept steam during startup, shutdown, load changes, or emergency trips. Without a Turbine Bypass Valve, excessive pressure and temperature can damage boilers, turbines, and condensers, which can cause costly downtime. In this article, we will explain how a Turbine Bypass Valve system works, the different types used in power plants, and its key applications in industrial operations.

Let’s start with what a Turbine Bypass Valve is.

What is a Turbine Bypass Valve?

A Turbine Bypass Valve is a high-capacity, fast-acting valve that is used in steam power plants. It lets steam bypass the turbine and flow directly to the condenser or other downstream equipment.

By doing this, a Turbine Bypass Valve protects turbines from excessive pressure and temperature stresses. It also ensures that the steam cycle continues smoothly even when the turbine is not available.

In industrial plants, it offers greater flexibility during startup and shutdown operations, improved safety by avoiding overpressure incidents, and lower costs because of reduced equipment wear and tear.

How Does a Turbine Bypass Valve System Work?

Generally, in power plants, steam passes through turbines to produce electricity. However, there are situations where the turbine cannot accept steam. In such a situation, the bypass valve comes into the picture.

1. Normal Operation

Whenever everything is calm and working properly, the Turbine Bypass Valve remains closed. Steam flows through the turbine as usual, generating electricity. The bypass path is quiet and unused.

2. Startup or Turbine Trip

If the turbine is offline during startup or if it trips, the bypass valve opens quickly. It allows the steam to pass through an alternative route. So, the steam pressure does not rise dangerously. It prevents the turbine from overheating or getting damaged.

3. Steam Conditioning

Sometimes the steam is too hot or too much. In such a situation, the system mixes cooler water with the hot steam, which is known as desuperheating. So, the steam cools down before entering the condenser or reheater. It protects parts from heat damage.

4. Pressure Control

The bypass valve manages steam pressure so the safety valve does not open unnecessarily. It means fewer shutdowns and more stable plant operation.

It means the Turbine Bypass Valve protects the turbines from sudden shocks of heat and pressure.

What are the Types of Turbine Bypass Valves?

Different stages of power plants require different bypass solutions. Here are a few main types of them.

1. High-Pressure Bypass Valve

High-pressure bypass valves are used in coal-fired and nuclear plants. This valve handles steam directly from the boiler at very high pressure and temperature. It can send steam directly to the condenser or to the reheater. For example, in the supercritical boiler plant, the HP bypass valve protects reheaters from pressure spikes during startup.

2. Hot-Reheat Bypass Valve

They are most commonly used in combined-cycle plants with HRSGs. They manage steam that has been reheated after passing through the part of the turbine. For example, in the 500 MW combined-cycle power station, the HRH bypass valve diverts reheated steam to the condenser when the turbine is offline, which prevents reheater overheating.

3. Low-Pressure Bypass Valve

It is used in both coal-fired and gas-fired plants. This valve manages cooler steam at low pressure. This valve is simpler in design as compared to HP and HRH valves. For example, In the gas-fired combined cycle plant, the LP bypass valve discharges steam to the condenser during low-load operations, which ensures stable performance.

What are the Industrial Applications of Turbine Bypass Valves?

The Turbine Bypass Valve are widely used in different types of power plants and large-scale industrial steam systems.

1. Coal-Fired Power Plants

In this type of power plant, HP and LP bypass valves are used. They protect turbines during startup and shutdown. It prevents boiler trips whenever turbine demand fluctuates.

2. Combined-Cycle Power Plants

HRH bypass valves protect the reheater from overheating. It ensures the gas turbine and HRSG can continue operation even if the steam turbine trips.

3. Nuclear Power Plants

The bypass valve handles excess steam in nuclear plants when the turbines are not running. It is important for safe reactor cooldown procedures.

4. Industrial Cogeneration Plants

In this type of plant, the bypass valve helps balance power output with process demand. For example, in the paper mill cogeneration unit, the bypass valve ensures steady steam delivery to process lines even if the turbine load changes.

What are the Benefits of a Turbine Bypass Valve?

The Turbine Bypass Valve offers the following benefits.

1. It Protects Expensive Equipment.

Steam turbines are the most expensive assets in the plant. If a single failure occurs, it can cost millions in repairs and lost production. The bypass valve prevents thermal and mechanical stress, which can shorten turbine life.

2. Turbine Bypass Valve Ensures Operational Flexibility

The Turbine Bypass Valve allows power plants to smoothly transition between the minimum and maximum loads within a short period. It ensures operational flexibility.

3. It helps improve Plant Safety.

High-pressure steam is extremely dangerous. A bypass valve provides a safe escape route, helping to prevent accidents and unplanned shutdowns.

4. Bypass Valve Reduces Emissions and Losses

The bypass valve often routes steam to the condensers instead of venting it directly to the atmosphere. It minimizes waste and reduces environmental impact.

In short, without a bypass valve, power plants have to face frequent shutdowns and high repair costs.

Final Thoughts

The Turbine Bypass Valves are essential for industrial power plants. Whether nuclear, combined-cycle, or coal-fired plants, these valves protect turbines, extend equipment life, and ensure the plants operate safely under all conditions.

At Vytal Control, we manufacture advanced bypass valve systems that perfectly meet the modern power generation requirements. Our solutions offer reliable protection for turbines, improve plant efficiency during startup, shutdown, and load changes, and durable designs built for long-term industrial use.

If you’re looking for safe, efficient, and reliable steam control, Vytal Control is the trusted partner for Turbine Bypass Valve solutions.