What is a Desuperheater?

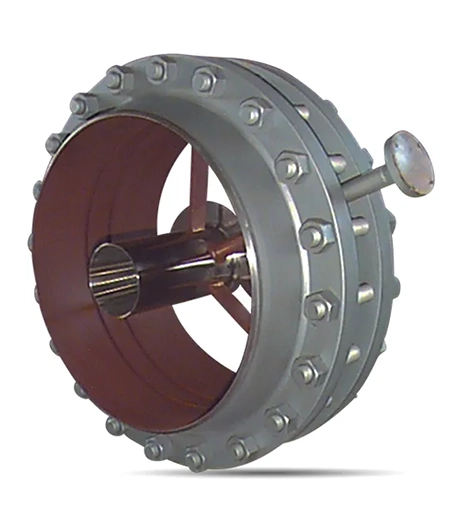

A desuperheater is an industrial device used to reduce the temperature of superheated steam to bring it closer to its saturation point — the temperature at which steam becomes water vapor. This process is called desuperheating.

Superheated steam is steam that has been heated beyond its boiling point without increasing pressure. While superheated steam is useful in many high-temperature applications such as turbines and power generation, some industrial processes require steam at lower temperatures. In such cases, a desuperheater becomes essential.

Improved Steam Quality With Effective Desuperheater Solutions

The principal function of any desuperheater is to accelerate the phenomena of absorption of the spray water by the steam so that steady conditions of steam temperature are reached within a short distance from the outlet at all loads. This ensures that poor-quality steam or water droplets are not carried downstream in the steam pipeline. The purpose, therefore, is to develop methods by which heat transfer between steam and water can be hastened.

The main purpose is to break spray water droplets into very fine particles at all loads to ensure increased surface area for water to come in contact with the steam available, thereby increasing the rate of evaporation. It is very clear that the size of the water droplets should be the smallest, utmost surface area available, absorption will be almost instantaneous and true temperature will be measured within the shortest distance.

In all instances of desuperheating, the nature of the downstream steam and the avoidance of large spray water droplets that can be propelled at high speed to damage elbows, valve seats, heat exchanger tubes, or process material are very important factors while designing a desuperheating system and equipment selection.

Technical Specification

Technical Specification for Desuperheaters.

Benefits of Desuperheaters

Desuperheaters are a crucial component in steam systems. It offers various benefits.

Get Expert Guidance and Tailor-Made Valve Solutions for Your Needs

FAQ

1. What is the function of a desuperheater?

The main function of a desuperheater is to cool down superheated steam by spraying a small amount of water into it. This water absorbs the extra heat, bringing the steam temperature closer to the saturation point (the temperature at which steam turns into water vapor).

This process is important because many industrial systems cannot handle very high temperatures. Desuperheaters help by:

-

Protecting equipment from heat damage

-

Improving efficiency in heat transfer

-

Controlling steam temperature for accurate processing

-

Saving energy and reducing operating costs

Desuperheaters are commonly used in power plants, refineries, food processing, paper mills, and other industries where controlled steam is essential.

2. What is the difference between a superheater and a desuperheater?

A superheater makes steam hotter by adding more heat to it. This is called superheated steam, and it's used in power plants and engines because it gives more energy.

A desuperheater does the opposite — it cools down superheated steam by spraying water into it. This brings the steam temperature back to a safe or needed level for other processes.

In simple words:

-

A superheater heats the steam up.

-

A desuperheater cools the steam down.